How Much Bolt Load Is Actually Being Created?

- Gregrey Majors

- 4 days ago

- 2 min read

Here’s the hard truth nobody likes to say out loud:

Most people have no idea how much bolt load they’re actually creating.

They know the torque number. They hope the joint is fine.

Hope is not a fastening strategy.

Torque Is the Input. Bolt Load Is the Result.

Torque is just rotational force.Bolt load (preload) is what actually holds things together.

And here’s the kicker:

👉 Only about 10–15% of applied torque becomes useful bolt load.

The rest? Lost to friction. Threads. Nut face. Surface finish. Coatings. Vibes. Mood. Mercury in retrograde.

Same torque. Same bolt.Wildly different preload.

That’s not theory. That’s real life.

Why This Goes Sideways in the Field

Let’s say you torque a bolt to 1,000 ft-lb.

Sounds precise. Looks professional. Feels official.

But bolt load depends on things nobody checks consistently:

• Thread condition

• Lubrication type (or “mystery grease”)

• Washer hardness

• Surface roughness

• Reuse vs new hardware

• Operator technique

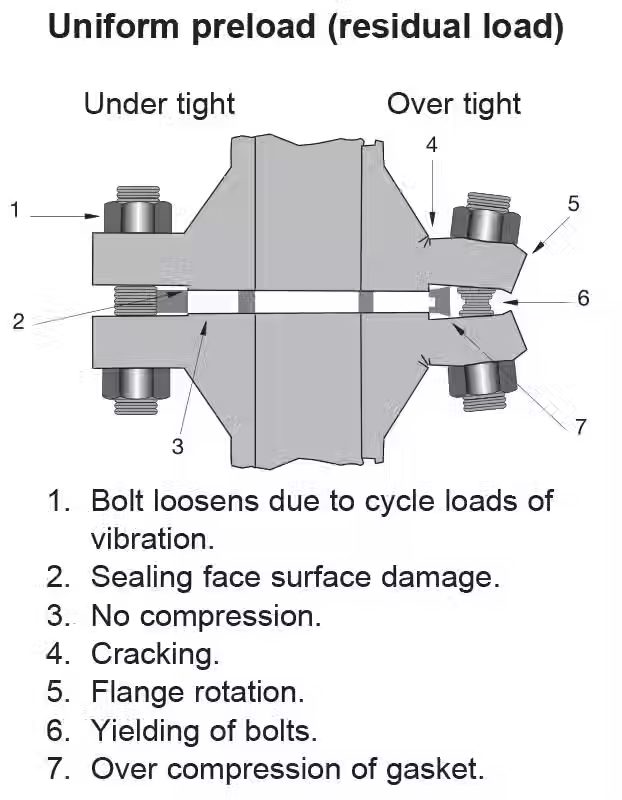

Change one variable and preload can swing ±30–50%.

That’s how joints loosen.That’s how flanges leak.That’s how startups get spicy.

The Torque Myth Everyone Believes

Torque feels controlled.Numbers feel safe.

But torque-only tightening is like judging engine power by how hard you turn the key.

You’re guessing.

A torque wrench doesn’t know:

• friction

• stretch

• yield

• clamp force

It just knows resistance.

And resistance lies.

So… How Much Bolt Load Are You Actually Creating?

Short answer:You don’t know unless you measure or control stretch.

Long answer:You have three real options.

Option 1: Torque (High Uncertainty, High Faith)

• Fast

• Familiar

• Cheap

Also:

• Huge preload scatter

• Inconsistent results

• Totally blind to actual bolt load

Torque is fine — when consequences are low.

When they’re not? Keep reading.

Option 2: Torque + Angle (Better, Still Not Bulletproof)

This adds a second control variable:

• Torque to seat

• Angle to stretch

It helps reduce scatter, but friction still plays games early in the process.

Better than torque alone.Still not the gold standard.

Option 3: Tensioning(This Is Where Bolt Load Gets Honest)

Hydraulic bolt tensioning directly stretches the fastener.

No guessing.No friction drama.No crossed fingers.

You apply a known axial force → you get a known bolt load.

That’s why critical joints use tensioning:

• Pressure vessels

• Wind turbines• Refineries

• Power generation

• Big flanges that ruin weekends when they fail

It’s boring.It’s precise.It works.

The Real Question You Should Be Asking

Not:

“What torque should I use?”

But:

“What bolt load does this joint actually need to survive startup, vibration, and thermal cycles?”

Torque is just the delivery method.Bolt load is the job.

The Takeaway (Read This Twice)

• Torque ≠ bolt load

• Same torque ≠ same preload

• Most joints fail because preload was wrong, not missing

• If bolt load matters, guessing is not acceptable

A torque wrench out of calibration is a suggestion stick.A torque value without preload context is a gamble.

And bolts? They don’t care how confident you felt tightening them.

Final Thought

Bolt load doesn’t announce itself when it’s wrong.It waits.

Usually until startup.Usually when everyone’s watching.

Get the load right — and everything else gets easier.

Comments